Testing Requirements - Specifies whether non-destructive testing of welds is required. Testing Category Within the Testing category, you can define the following values, as shown in Figure 5:įigure 5: Testing Category in the New Pipe Run Dialog Box

#SP3D EQUIPMENT TUTORIAL PDF SOFTWARE#

If the piping specification rules do not allow you to override components, then the software disables this option.Ĭorrelation Status - Displays whether the pipe run has been correlated to a pipe run in a P&ID.Ĭorrelation Basis - Specifies if the pipe run needs to be correlated to a P&ID pipe run. Schedule Override - Specifies the thickness override for parts in the pipe run. O In degrees, a 5 degree slope can be specified as 5 deg. O As a percentage, if a run drops 1 in for every 10 inches of horizontal distance, specify the slope as 10%. O As a ratio, if a run drops in for every foot of horizontal distance, specify the slope as inch/1 ft. You can specify the slope as a ratio, as a percentage, or in degrees. Minimum Slope - Specifies the slope for the pipe run. If you select an equipment nozzle as the starting point of your pipe run, the software automatically uses the flow direction of the nozzle as the flow direction of the pipe run. You can select the NPD units to be displayed in a session file basis by using the Tools > Options command on the Units of Measure tab.įlow Direction - Selects the direction of flow for the pipe run. If you select an equipment nozzle as the starting point of your pipe run, the software automatically uses the NPD of the nozzle as the NPD of the pipe run. The pipe specification controls the available NPDs in this list. Nominal Diameter - Selects the NPD to use for this pipe run. Specification - Selects the pipe specification which will control the pipe run. You can select one of the listed rules or specify the pipe run name in the Name box. Name Rule - Specifies the naming rule to name the pipe run. If you specify a name in this box, the software automatically sets the Name Rule box to User Defined. The pipe run name is based on the Name Rule selection. Name - Displays the name of the pipe run. Pipeline - specifies the pipeline system to which the pipe run will belong. Standard Category Within the Standard category, you can define the following values, as shown in Figure 4:įigure 4: Standard Category in the New Pipe Run Dialog Box Pipe run properties are divided into different categories as follows: You can select the category for which you want to define values by using the Category drop-down list in the New Pipe Run dialog box, as shown in Figure 3. You can view and make changes to the default properties of a pipe run by using the New Pipe Run dialog box. The New Pipe Run dialog box appears when the user creates a new pipe run. The Piping System Properties dialog box appears where the default properties of a pipe run are defined.įigure 2: Piping System Properties Dialog Box To access the properties, you right-click the Process system in the Workspace Explorer and select the Properties command, as shown in Figure 1.įigure 1: Accessing the Properties of a Piping System If these properties are defined in a piping system, then the entire pipe run modeled under piping system will inherit these properties.

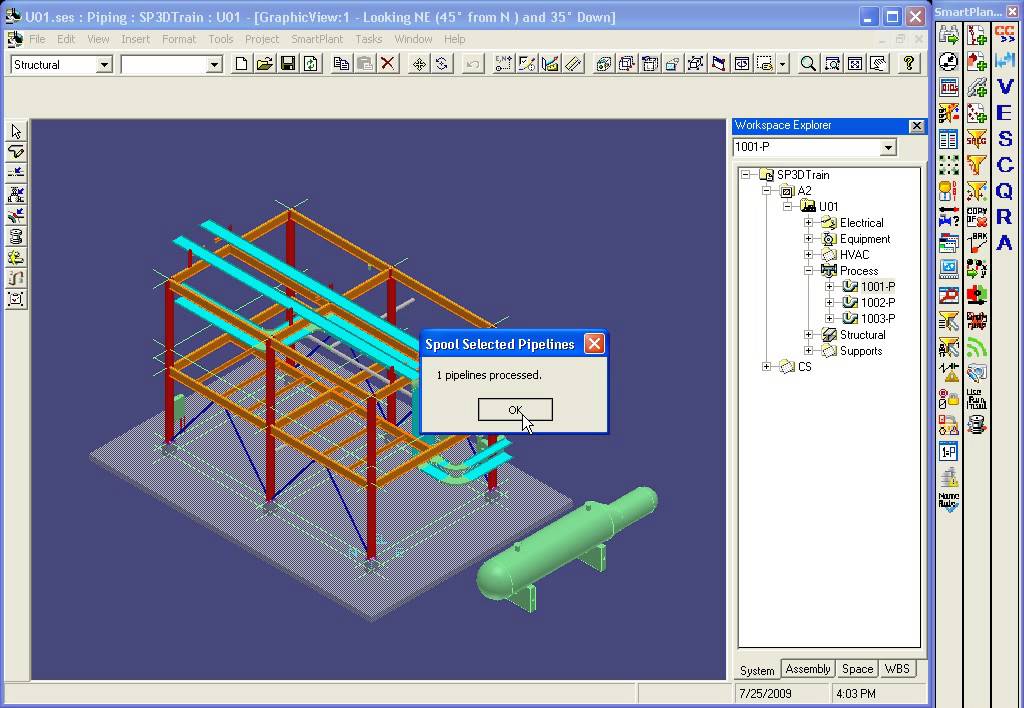

The default properties of the parent piping system defined in the Systems and Specifications task of SP3D. Default properties for the new pipe run can be defined from any one of the following: Overview: In SP3D, when you route a pipe and create a new pipe run in a model, you need to set the default or common properties of the new pipe run at the system level. Identify the default properties of pipe runs in a system. Session 2: Routing Pipes Objectives: By the end of this session, you will be able to: Last Updated: Apfor Smart Plant 3D 2009 of 24

0 kommentar(er)

0 kommentar(er)